Revolutionize Your Business with High-Quality Label Applicators

In today's fast-paced business environment, operational efficiency and accuracy are paramount. One essential component that significantly enhances these aspects is the use of label applicators. Whether you're involved in printing services, electronics, or computers, the right applicator can transform your labeling processes, ensuring that every product leaves your facility with the appropriate identification.

Understanding the Role of Label Applicators

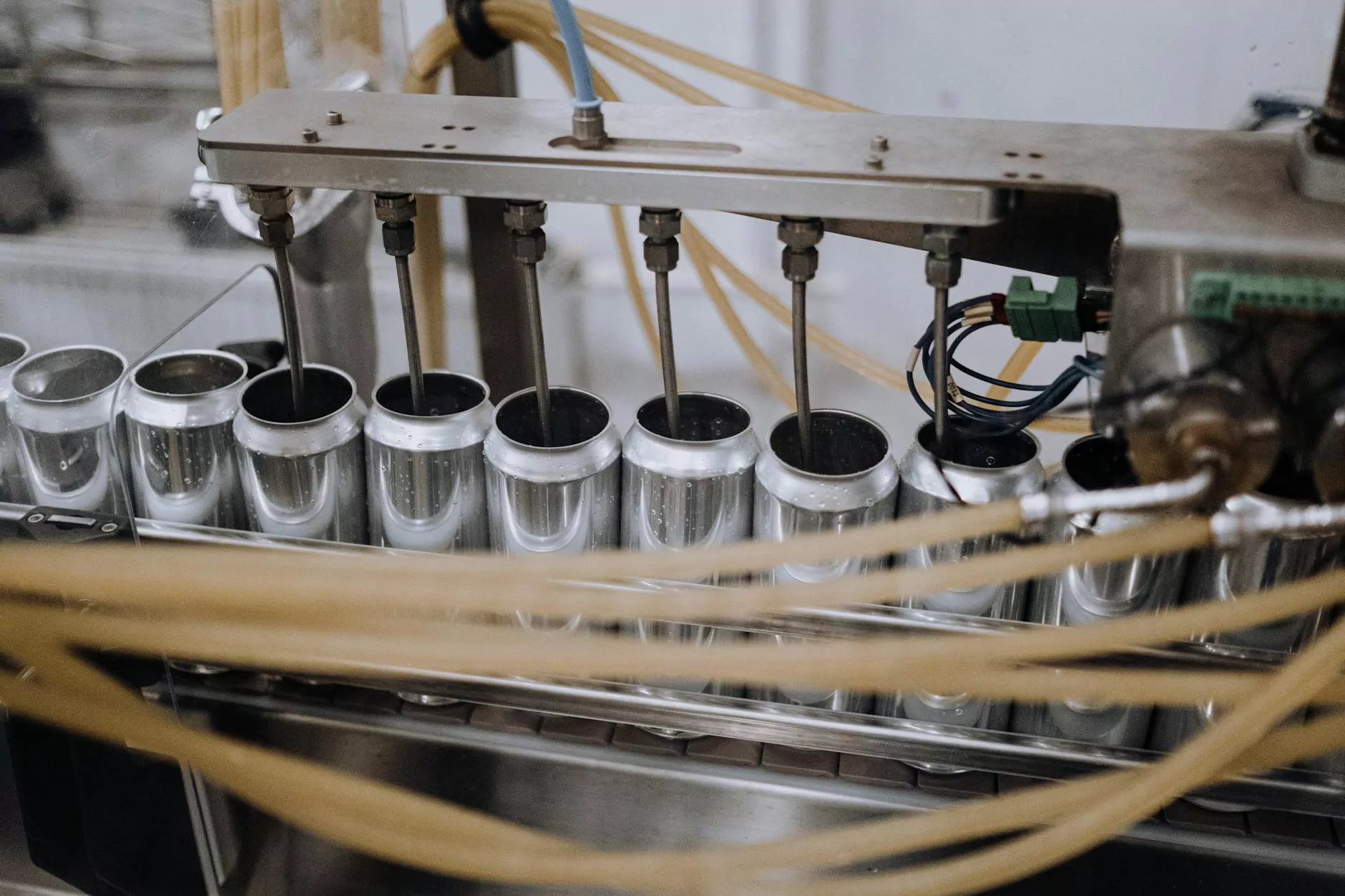

Label applicators are specialized machines designed to automate the process of applying labels to products, packaging, or any surface that requires identification. They are a boon for businesses that aim to streamline their production processes. With the ability to operate at high speed and maintain precision, these machines significantly reduce the risks associated with manual labeling.

The Benefits of Utilizing Label Applicators

Integrating label applicators into your business operations offers a multitude of advantages:

- Increased Efficiency: Automating the labeling process reduces the time employees spend on manual tasks, thereby increasing overall production efficiency.

- Improved Accuracy: Automated label application minimizes human errors, ensuring that every label is correctly positioned and aligned.

- Cost-Effective: While the initial investment in labeling machinery might seem high, it can lead to substantial savings in labor costs and waste reduction over time.

- Versatility: Modern label applicators come with various settings and capabilities, allowing businesses to handle different label types and sizes easily.

- Enhanced Brand Perception: Consistently applied labels enhance product presentation, building customer trust and improving brand loyalty.

Types of Label Applicators Available at OmegaBrand

At OmegaBrand, we offer a diverse range of label applicators tailored to meet the unique needs of businesses across various industries:

1. Manual Label Applicators

For small businesses or those just starting, manual label applicators provide an economical solution. These devices are easy to use and require minimal maintenance. They are ideal for low-volume labeling tasks but can still deliver high-quality output.

2. Semi-Automatic Label Applicators

These machines strike a balance between manual and fully automated systems. They require some operator involvement but significantly enhance speed compared to manual application. Semi-automatic applicators are perfect for businesses with moderate labeling needs.

3. Fully Automatic Label Applicators

For high-volume production environments, fully automatic label applicators are the best choice. These robust machines can label thousands of products per hour with unparalleled precision. They are equipped with advanced technology to ensure seamless integration into existing production lines.

Factors to Consider When Choosing Label Applicators

When selecting the appropriate label applicator for your business, consider the following factors:

1. Production Volume

Assess how many products you label daily. High-volume businesses will benefit more from automatic machines, while low-volume operations can opt for manual or semi-automatic options.

2. Label Size and Type

Your choice of applicator should accommodate the various sizes and types of labels you'll be using, from small barcodes to large shipping labels.

3. Integration with Current Systems

Ensure that the label applicator you choose can be easily integrated into your existing production line without causing significant downtime.

4. Maintenance and Support

Consider the availability of maintenance and customer support. A reliable manufacturer like OmegaBrand will provide technical assistance and spare parts as needed.

How to Optimize the Use of Label Applicators in Your Business

To get the most out of your label applicators, consider implementing these best practices:

1. Regular Maintenance Schedule

Proactively maintaining your machines prevents breakdowns that can halt production. Schedule regular check-ups and routine cleaning to keep your applicators in optimal condition.

2. Training for Operators

Train your staff on how to operate and troubleshoot the applicators effectively. Well-trained employees can maximize the efficiency and lifespan of your labeling machinery.

3. Monitoring Production Metrics

Invest in software that tracks your production metrics related to labeling. Understanding your throughput and error rates can help identify areas for improvement.

4. Keep Up with Technology

As technology advances, consider upgrading to more efficient models or adding features that enhance your label applicator capabilities.

Conclusion

In conclusion, high-quality label applicators are not just an operational tool; they are a strategic investment that can propel your business forward. By elevating efficiency, enhancing accuracy, and ensuring a professional appearance for your products, these machines serve as a critical component in your production line. Explore the comprehensive range of products available at OmegaBrand to find the perfect labeling solution tailored to your business's needs. Streamline your operations today, and watch your productivity—and profits— soar!

For a consultation or to get started on enhancing your business operations with the best label applicators on the market, reach out to OmegaBrand today!